DISHING PRESS WITH MANIPULATOR BSPM 250 – 3500

Technical Specifications:

- Pressing Force :250 Tons

- Distance Between Columns :3500 mm

- Max. Blank Diameter of Dished Head :3500 mm

- Min. Blank Diameter of Dished Head :1600 mm

- Max. Pressure :230 Bar

- Diameter of Cylinder :Ø360+ Ø100×2 mm •

- Stroke :600 mm

- Motor Power :30+5,5 kW

- Weight(approx.) :16500 kg

- Overall Dims. (L-W-H) :6200X6500X4300 mm

Bending capacities are calculated based on 240 N/mm2 Yield Point.

- General Specifications:

- They are the machines which are used for manufacturing dished head covers for cylinders.

- Tank Dishing, Torispherical Dishing, Elliptical Dishing, 2:1 Elliptical-Ellipsoidal, Plain Dishing.

- Operation: Automatic with PLC controlled manipulator for round dished ends.

- Hydraulic Equipments: Motor & pump group, valves, solenoid valve, Eaton(UK) parts are used.

- Electrical Equipments: Lovato(Italy).

- PLC Controller: Panasonic(Japan).

- Emergency System: Emergency button.

- Built according to EC Safety Directives.

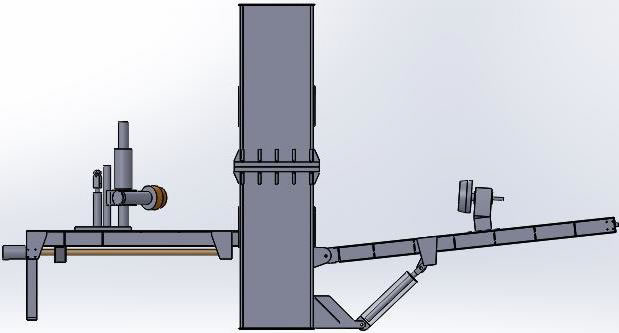

HYDRAULIC DISHING PRESS WITH MANIPULATOR

- Working System:

- This process is forming the sheet according to shape of mold by pressing of hydraulic cylinder to the sheet.

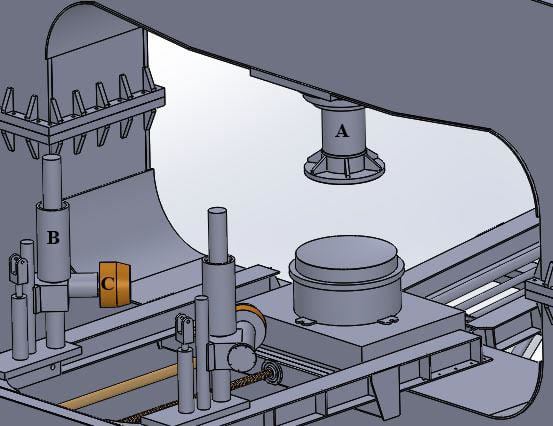

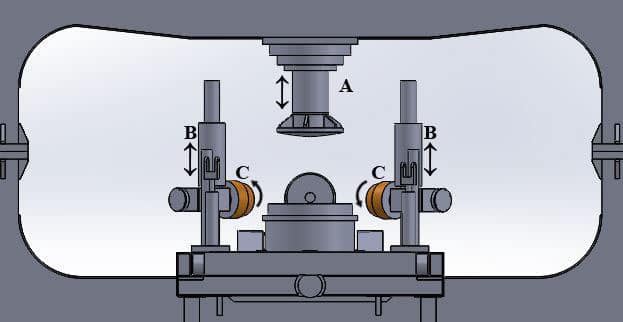

- Later, main hydraulic piston A applies force to press sheet metal and forming process is started.

- The main hydraulic piston A moves up. Then Cylinders B moves up to support sheet metal.

- After support rollers C touches sheet metal, the sheet metal moves little up and support rollers C turn in the counter-clockwise direction. By this way sheet metal moves in clockwise direction as it is expected.

- After a period of spinning of sheet metal, support rollers C moves down and pressing is carried out again. The process is repeated until the sheet metal has a dished head shape with expected dimensions.