High-precision Forging hydraulic presses engineered for forging of hot metals used for industrial applications.

Elmali Engineering UG is the first company to develop and manufacture CNC‑controlled hydraulic forging hammers, engineered under our TRtech brand. With more than 40 years of industrial experience and over a decade of specialized manufacturing expertise, we are redefining forging technology with machines designed for maximum precision, efficiency, and durability. Our fully domestic production capabilities enable us to deliver forging systems that meet the highest standards of modern industry.

Developed through the advanced research of our R&D department, our CNC‑controlled hydraulic forging hammers offer exceptional accuracy, automated process control, and significant energy savings. By combining high impact force with user‑friendly CNC interfaces, robust construction, and simplified maintenance, these systems provide an ideal solution for manufacturers seeking speed, repeatability, and superior forging quality

Every component of our forging hammer systems is produced entirely in‑house. This ensures full control over quality, performance, and long‑term reliability—demonstrating the strength of our domestic engineering and production capabilities.

With our TRtech brand, we are now introducing our CNC‑controlled hydraulic forging hammers to global markets, starting with Europe. By showcasing our engineering expertise and domestic production strength on the international stage, we are committed to contributing to our country’s industrial growth and establishing a strong global presence.

This achievement reflects decades of experience, engineering excellence, and dedication to customer needs. Our CNC‑controlled hydraulic forging hammers mark the beginning of a new era in industrial forging—delivering precision, automation, and performance that set new standards for the industry.

Depending on the size and geometry of the workpiece, table dimensions can be manufactured up to 1200 mm. This allows large billets and complex forged parts to be processed under stable and controlled conditions.

Demonstrates the maximum table capacity of TRtech forging systems — essential for customers handling large or heavy workpieces.

To prevent vibration during press operation, the spring‑damper system absorbs shocks and oscillations. This protects the press, the foundation, and the surrounding environment from excessive mechanical stress.

Improves precision, reduces wear, and ensures a stable, low‑vibration forging process — essential for CNC‑controlled TRtech presses.

Iron pieces heated to forging temperature (typically 500–1000 °C) are shaped into the desired form inside the press. The combination of heat and high pressing force enables precise forming and high material strength.

Shows the real forging process for which TRtech hammers and presses are designed: high temperature, high load, precise forming.

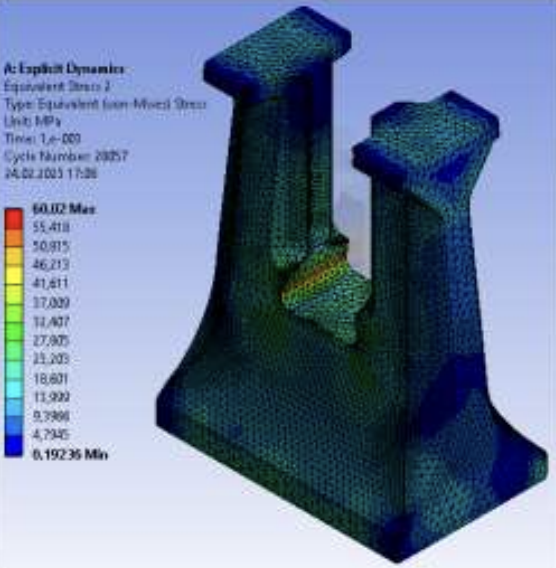

The strength of the press body is designed and analyzed using SolidWorks. Finite Element Analysis (FEA) allows potential deformations, stress concentrations, and critical areas to be identified in advance during the design phase.

Ensures that TRtech presses withstand extreme forces, remain durable, and operate reliably under industrial conditions.